xps sandwich panel

| Place of Origin: GUA,GUANGZHOU China (Mainland) | Brand Name: SOLO | Panel Material: Nonmetal | Type: XPS Sandwich Panels |

| Condition: New |

You can trust a company with over 12 years of fiberglass panel manufacturing experience.

Our Commitment

Quality

Innovative Custom Solutions

Competitive Pricing

Timely Delivery

Personal Attention to Customers of All Sizes

Construction Characteristics

1 ) FRP with polyurethane foam panels (PU sandwich board) are made of prefabricated fiberglass reinforced plastics sheet and polyurethane foam, by vaccum bonding in high pressure. Due to woven roving with high strength, the panel has good property in shock resistance and flexural strength.

2 ) The color gelcoat used on the surface is of iso-phtalic-NPG based resin, FDA approved. It makes the surface of panels smoother, brighter and easier to clean. Good gloss retention is guaranteed.

3 ) The maximum dimension of panel is 10 meters long, 3 meters wide,and we can also produce according to customers requirements.

Performance

1) FRP sheets,the surface of panels, have impermeability while unicellular rate of polyurethane foam is bigger than 90%, so the composite panels have excellent property of water resistance.

2 ) Heat-Shielding Performance: The general heat conductivity coefficient of 80 mm thick PU sandwich panel is lower than 0.3W/.K, which is much better than iron and aluminum panels.

3 ) Surface Performance: The surface of FRP sheet has a layer of premium gelcoat which gives the panels better chemical stabilization to air, water and normal medium such as acid, alkali and salt. It is the gelcoat that makes panels have good gloss retention, and can keep smooth appearance after long time using, non-fading, corrosion resistance, anti-UV, anti-aging, which gives it the priority to make big advertisement.

4 ) Maintainability: Panels are easier to repair, no evident mark left, which the steel and aluminum panel can hardly compare with.

Main performance Date

| Foam-cored FRP Composite Panel | |||

| No | Item | Date | |

| 1 | Thermal conductivity W/m.K≤ | 0.025 | |

| 2 | Compressive strength Kpa≥ | 200 | |

| 3 | Barcol Hardness≥ | 40 | |

| 4 | Impact Strength KJ/M2≥ | 15 | |

| 5 | Edgewise compressive Strength Mpa≥ | 2 | |

| 6 | Flatwise compression Strength Kpa≥ | 210 | |

| 1050a | |||

| 7 | Bending Rigidity GPA≥ | 7 | |

| No | Panel's thickness(mm) | weight(kg/m2) | |

| 1 | 30 | 10.5 | |

| 2 | 45 | 11 | |

| 3 | 70 | 12.5 | |

| 4 | 105 | 13.5 | |

| 5 | 130 | 15 | |

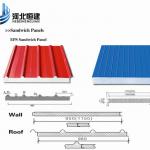

Main application range

Heat Preservation box, freezer box, chiller box, dry goods box, large-span structure roofing,wall surface, heat preservation, heat insulation and fire proofing factory, various composite house, refrigeratory, container house and so on.It is the best insulation material in the world.

Grip core board stop fire index conform to the National standard B2 step

Our products have been exported to many countries for years and enjoyed great reputation.

Our oversea markets are as follows: North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe etc

| Packaging Detail:standard packing for export |

| Delivery Detail:25Day |