Shunan Reinforced Cement based, Mineral Finish for EWIS - SA802

| Place of Origin: Shanghai China (Mainland) | Brand Name: Shunan | Model Number: SA802 | Usage: Joint Mortar |

| Type: Cement Mortar | Composition: Cements and additives, Sand, Polymers | Application: External Wall Insulation System Basecoat |

Shunan SA802 mineral adhesive and basecoat For ETIC Systems

A comprehensive line of base coats and adhesives used to embedded mesh or adhere EPS/XPS to approved substrates or EPS/XPS.PRODUCT INFORMATION

PRODUCT PACKAGING

Weight: 25kg

Color: Natural cement gray

Consumption: 5~6 kg/m2

Shelf life and storage: 6 months after manufacturing date in dry ventilated place

Standard: JG149-2003

EPS adhesive for the following substrates:

1. Exterior grade gypsum sheathing

2. Glass Mat gypsum sheathing

3. Masonry, concrete and cement board

4. EPS

Field of application:

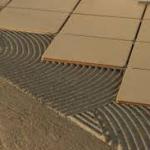

The function of this product is to protect the XPS board and fix the mesh. The finishing coat can be tile or plater, paint etc...

Remarks:

1) Only mix with water, no other addition

2) The temperature of air and glue must be from 5°C~35°C

3) The glue must be used up in 2h

4) Avoid sunshine, high temperature and freezing

5) Avoid strong wind during application

6) Avoid rain during application

Consumption

4.5 ~ 6 kg/m2

Product specification

Items | Data | |

Tensile Adhesive strength, Mpa (with foamedpolystyrene) | Original | ≥ 0.10 (polystyreneboarddamaged) |

| Water resistant | ≥ 0.10 (polystyreneboarddamaged) | |

| Freeze - thaw resistant | ≥ 0.10 (polystyreneboarddamaged) | |

Flexibility property | Compressive strength/ flexural % (cement based) | ≤ 3.0 |

| Cracking strain % (non cement base ) | ≥ 1.5 | |

Processing/working time h | 1.5~4.0 | |

Tools

electric-mixer,trowel,bucket

Substrate requirement

1) Polystyrene board must be clean (no dust or dirt)

2) Polystyrene board must be fixed stably (Wait min 24h before applying shunan. therm epsad)

• Make sure the whole polystyrene wall is flat

Application enviroment

1) Temperature:5°C~35°C

2) Avoid raining, high temperature and frost

3) Avoid direct sunlight and class 5 wind

SA802 is a part of external wall insulation systems (or EWIS) of external building walls

Typical ETICS Configuration (Polymer Render Systems)

1. Concrete or Masonry Substrate

2. Adhesive Applied to Insulation Board (SA801)

3. Insulation Board

4. Base coat (SA802)

5. Fiberglass Mesh

6. Base Coat(SA802)

7. Flexible External Wall Finish Putty

8. Finish Coat

| Packaging Detail:In 25 kg paper bags |

| Delivery Detail:5 days |