PVC Jointers for Connection of Panel

| Type: Plastic Profiles | Place of Origin: Zhejiang China (Mainland) | Brand Name: Lucky | Length: 5.95m, Depends on your requirement |

| Color: Hundreds of patterns and colors | Celling tile type: PVC Celling |

We are a professional PVC Ceiling panel manufacture since 1992, offering hundreds of patterns and colors of PVC panel and monthly output up to 480000Sqms.

Different types of PVC Panel we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

4, Transfer Printing PVC Panel

The hottest specifications of PVC panels on the market:

Length: 3m-6m as request.

Width: 200mm/250mm/300mm/600mm

Thickness: 4mm/4.5mm/6mm/7.5mm/8mm/9mm/11mm

PVC percentage: 35%-75%

Any other specifications are also available here.

The hottest type/specs of the PVC panel: | |||||||||

Luck PVC | PVC CONTENT | Width | Thickness | Length | N.W. | Packing | Loading in a 40'HQ | ||

| mm | mm | M | Kg/Sqm | packages | amount/Sqm | ||||

| 1 | 35%-75% | 200 | 5 | 5.95 | 1.7 | 10 pcs/PE film package | 1142 | 13589.8 | |

| 2 | 6 | 5.95 | 1.9 | 900 | 10710 | ||||

| 3 | 7.5 groove | 5.95 | 2.1 | 745 | 8866 | ||||

| 4 | 8 | 5.95 | 2 | 714 | 8496.6 | ||||

| 5 | 250 | 4 | 5.95 | 1.5 | 1070 | 15916 | |||

| 6 | 4.5 | 5.95 | 1.65 | 941 | 13997 | ||||

| 7 | 7.5 | 5.95 | 2.2 | 591 | 8791 | ||||

| 8 | 11 | 5.95 | 3.9 | 416 | 6188 | ||||

| 9 | 300 | 9 | 5.95 | 2.5 | 429 | 7658 | |||

10 | 595/600 | 7 | 0.595 | 2.9 | 20pcs/carton | 1160 | 8213 | ||

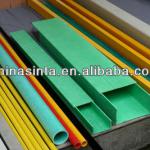

Hundreds of patterns & colors are provided. New patterns are adding ceaselessly, which can keep you on the front of the market

Application

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

Feature:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

Quality Test:

| No. | Test Items | Technical Requirements | Detection Result | Single Judge | |

| 1 | Appearance | Fulfill | Qualified | ||

| 2 | Flexibility mm/m | <1.5mm/m | 0.48 | Qualified | |

3 | Thickness mm | Faceplate | >0.4 | 0.4 | Qualified |

| Base plate | >0.3 | 0.32 | |||

| 4 | Heating Rate % | <6.0 | 0.6 | Qualified | |

| 5 | Heated State | No bubble, craze or spot | Fulfill | Qualified | |

| 6 | Resistance of acetone | No defects | Fulfill | Qualified | |

| 7 | Dart drop impact | 0.25kg/0.5m,10 times, Pass when keep unbroken above 6 times | pass | Qualified | |

| 8 | Size Variation in High/Low Temperature | ±0.6% | -0.16 | Qualified | |

| 9 | Nail resistance | no visible cracks | Indehiscent | Qualified | |

PVC Panel Production Process:

A) Main Raw Material: PVC Resin and Calcium Carbonate, More PVC Resin better quality.

B) Step 1: Mixing Machine mixes the PVC Resin, Calcium Carbonate and others material thoroughly.

Step 2: Molding machine heat the raw material to make it as whole PVC by 230degree temperature.

Step 3: The mold pile out the PVC, and then change it as semi-manufactured PVC panel goods.

Step 4: Put the semi-manufactured PVC panel on the printing machine to print design and color and PVC resin oil on the PVC panel.

About us:

1. Has a certain degree of the scale and efficiency till now

2. Advanced printing machines

3. Twenty lines work together

4. Treat every order with responsibility

5. Rich experience in export to countries from Middle East, South Africa, Southeast Asia, South America and so on.

Welcome to visit our factory, welcome all interested parties to establish long terms business relationship with us under the mutual benefit and kindly friendship.

| Packaging Detail:10 pcs. in per pe film package |

| Delivery Detail:7-10 days |