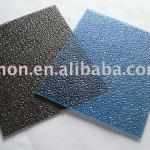

polycarbonate compact sheet - TN260

| Type: Sun Sheets & PC Embossed Sheets | Place of Origin: Guangdong China (Mainland) | Brand Name: China Nature | Model Number: TN260 |

| Polycarbonate solid sheet: Manufacturer | brands: China Reid, Sun Nature. Tonon | kinds: small / big diamond | Color: Brown, Orange, Green, Grey, Blue, Red, Clean, Transparent, Opal, White |

| Material: PC marklon resin | Thickness: 2.0mm to 18mm | Size: Max width: 2100mm | Length: without limitation |

| quality gurantee: 10 years | Location: Guangdong |

Company Introduction:

Foshan Tonon Building Materials Co., Ltd is high-tech and new-tech enterprise in Foshan City specializing in prodution of polycarbonate panels (including polycarbonate sheets and sun-panels). The PC sun-panels use pure imported environment-friendly raw material and lasted German technology. The quality management is built and implemented in accordance with GB/T19001:2000ibit and ISO9001:2000 quality management systems requirements. High-level team, advanced technology and first-class manufacture facilities ensure first-class product quality o Tonon.

Tonon Company always takes it as the foundation of enterprise to provide customers with high quality and high standard PC sun-panel, and more importantly, take safety and environmental protection responsibility as development orientation of enterprise. The enterprise will carry forward the tenet of "creating famous-brand products and building an enterprise with our own characteristics".

With innovation as goal, guided by the qualty policy of "wholehearted service, constant advancement and constant improvement", we will keep striving for new, characteristic and excellent products; with strong technical force, modernized excellent facilities, high-efficiency management mode, strict quality control system, perfect quality assurance system, we will provide customers from around the world with first-class products and firs-class service.

FEATURES:

1)Impact strength: The impact strength of solid polycarbonate compact sheet is 250 times that of glass, and the impact strength of polycarbonate compact sheet is 80 times that of glass

2)Light weight: the weight of a polycarbonate compact sheet is only about half of glass, and the weight of a hollow PC sheet is only about one twelfth at the same thickness

3)Transparency: The light transmission of a 3mm solid polycarbonate compact sheet is 88%, and the light transmission of 6mm hollow PC sheet is 80%

4)UV-protection: polycarbonate compact sheet is co-extruded with a high-density ultra violet ray that also keeps the PC sheet from discoloring

5)Resistance to weather: A PC sheet has resistance to bad weather and maintains excellent properties in a wide temperature range from -40°C to 120oC

6)Inhibiting condensation: When the outdoor temperature is 0oC and the indoor temperature is 23oC, the PC sheet will be

condensation up to 80% humidity

7)Thermal insulation: The K-value of glass is 1.2 times that of solid a PC sheet and is 1.7 times that of a hollow PC sheet. PC sheets saves energy while preventing heat loss

8)Sound insulation: The hollow form and polycarbonate resin offers significant advantage to that of glass

9)Flame Resistance: Through testing by the National Center for Quality Supervision & Testing of Fire Building Materials, the

material is rated as Class B1 according to QB8624-1997 standards

10)Easy installation:A PC sheet can be bent while hot or cold and can be used on curved roves and windows. The minimum radius of curvature of a PC sheet is 175 times of its thickness.

Technical features of Tonon Polycarbonate Compact Sheet:

| No. | Character istics | Unit | Data |

| 1 | Impact Strength | J/m | 850 |

| 2 | Light Transmission | % | 88 |

| 3 | Specific Gravity | g/cbm | 1.2 |

| 4 | Coefficient of Thermal Expansion | mm/m °C | 0.065 |

| 5 | Service Temperature | °C | -40 °C ~+120 |

| 6 | Heat Conductivity | W/ sqm * °C | 2.3~3.9 |

| 7 | Tensile Strength | N/sqmm | ≥ 60 |

| 8 | Flexural Strength | N/sqmm | 100 |

| 9 | Modulus of Elasticity | Mpa | 2400 |

| 10 | Tensile Stress at Break | Mpa | ≥ 65 |

| 11 | Elongation at Break | % | >100 |

| 12 | Specific heat | KJ/kg*k | 1.17 |

| 13 | Heat Deflection Temperature | °C | 140 |

| 14 | Effect of Soundproof | 10mm PC Hollow Sheet | Attenuation 20 db |

| Country | Standard | Thickness |

| Italy | D.M.26.6.84.art8 | 6.10.16 |

| UN | B.S.476-PART,7-187 | 10.16 |

| Germany | DIN 4102 | 6.8.10.16 |

| France | Nf-p-92-507 | 6.8.10.16 |

| China | GB 50222-95 | 6.8.10.16 |

Applications:

1) Roofing for swimming pool, shopping malls, commercial streets

2) Sunshade for stadiums and bus stops, gazebo, open-air carport

3) Lighting canopy for corridors, passages and subway entries

4) Flashing for bank ATMs, telephone box, gateways, garages

5) Sound and heat insulation wall for expressways and houses

6) Heat preservation material for agricultural greenhouse, flower greenhouse

7) Soundproof material for partitions

8) Unbreakable material for glazing windows, roof glazing

Certification:

Max width: 2100mm, Length: no limit

Thickness: from 3.8mm to 16mm

Material: Makrolon Pc resin from Bayer, Germany

Product line: 2 lines for hollow pc sheet and 1 line for solid pc sheet

Customized colors and dimensions available upon request contact us!

Raindrop pc sheet

solid sheet:

Clean And Maintenance:

In case there is any filler, grease or paint adhered or polluted the surface of the pc sheet, remove it with a piece of soft cloth soaked with alcohol it become hardening. Never use the benzene, gasoline, acetone or carbon tetra chloride of cleaning, do not clean the sheet with any solvent exposed under direct sunshine or under forced bending, for it may crack. Generally wipe off the dust and dirt on the pc sheet by a piece of soft cloth or sponge soaked with neutral detergent first, rinse it with clear water thoroughly, and dry it with a piece of soft cloth finally.

To customers and readers:

This information and our technical advice whether verbal, in writing or by way of trails are given in good faith but without warranty, and this also applies where proprietary rights of third parties are involved. Our advices does not release you from the obligation to check its validity and to test our products to their suitability for the intended process and uses. The application, use and processing of our products and the products manufactured by you on the basis of our technical advice are beyond our control, therefore, entirely you own responsibility. Our products are sold in accordance with the current version of our General Conditions of Sales and Delivery.

| Packaging Detail:Both sides are covered with the PE protective film |

| Delivery Detail:6 days after receipt 30% deposit |