non oxidization aluminum composite sheet/wooden panel - xh20120625

| Place of Origin: Guangdong China (Mainland) | Brand Name: Megabond,Kingaluco | Model Number: xh20120625 | Usage: Outdoor |

| Function: Anti-Static,Antibacterial,Fireproof,Mould-Proof | Surface Treatment: Anodized,Brushed,Foil Decoration,Mirror,PE Coated,Printing,PVDF Coated,NANO | Color: Any color is accepted | Coating: PE/PVDF/NANO |

| Aluminum Thickness: 0.12-0.5mm | sandwich Thickness: 2-6mm | Standard Size: 1220*2440*4*0.3mm | Quality Assured: PPG,SGS,ISO,KNYAR 500 |

| After-sales: If quality issue can be refund | Sample: Free but shipping | MOQ: 600sqms per color | Package: Wooden pallet/in bulk |

non oxidization aluminum composite sheet/wooden panel 1.Specification | |

| Brand Name | Megabond, kingaluco |

| Coating | PVDF & Polyester & Nano |

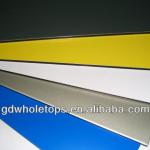

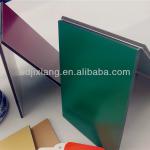

| Colour | 60 kinds of colour, Mirror, wooden and marble design, brush, fireproof |

| Standard size | 1220mm x 2440mm x 3mm; 1220mm x 2440mm x 4mm |

| Thickness | 1mm, 2.5mm, 3mm, 4mm, 5mm, 6mm |

| Thickness of aluminum | 0.15mm-0.5mm |

| Width | 1220-1570mm |

| Length | 2440MM (According to customer’s requirement) |

| Weight | 5.5-6kg/sqm based on 4mm thickness |

2. Product structure

3. Characteristics

1) Well weather-resistance, high rigidity, easy for maintenance, only neutral cleanser and water needed for its self-clean performance;

2) Easy finishing with conventional working tools. Short time needs for project;

3) Good workability, fire-resistance, heat sound insulation;

4) High flexibility and impact-resistance, superior surface flatness, lightweight, rigid;

5) Various colors are available according to your needs;

6) Competitive price and quick delivery.

4. Application

·Exterior applications as:

Wall cladding, facades, roofs and canopies, tunnels, column covers or renovations.

·Interior applications as:

Wall cladding, ceilings, bathrooms, kitchens and balconies.

·Advertisement and market applications as:

Display platforms, signboards, fascias and shop fronts etc.

-TransportIndustry applications

5. Material

1) 3-layers PVDF coating, material is sourcing from PPG (U. S. A) INDUSTRIES, INC. HYLAR5000

2) Aluminum coils supplied by SOUTHWEST ALUMINUM (GROUP) CO., LTD. ALCOA (U. S. A)

3) Protective film from Novacel, France

4) PE-incore is from SINOPEC QILU COMPANY LTD.

5) Adhesive polyfin film is made by SK Korea, more than 90 degrees.

Quality Test By time andWeather

This is the aluminum wall cladding material in our factory clearing ,to test the strength for resisting bad weather.

Sandwich panel show:

Projects

Including the shop decoration ,bank,office ,gas station.

Factory Around

Certification

How to Load FCL/LCL

| Packaging Detail:in bulk or with strong wooden pallets |

| Delivery Detail:within 7-12 days after 30% TT deposit |