Machine for Cement Fiberglass Mesh XPS Tile Backer Board - JL-XPS135/150

| Type: XPS Boards | Place of Origin: Hebei China (Mainland) | Brand Name: Golden Deer | Model Number: JL-XPS135/150 |

| Material Of Chain Board: Aluminum / Steel | Name: Machine for Cement Fiberglass Mesh XPS Tile Backer Board | Feature: Automatic | Heating Power: 52KW |

| Driving Power: 45KW | Product width x thickness: 600 X (20-150)mm | Production Capacity (approx): 250m³/d | Installed Capacity (approx): 300KW |

| Machine Weight (approx): 20T | Woking Voltage: 380V / Customization |

Machine for Cement Fiberglass Mesh XPS Tile Backer Board

Product Introduction

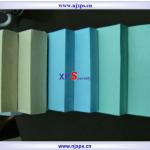

XPS extruding polystyrene foamed panel, also named as expanded polystyrene extruded board (XPS for short) has a perfect closed-pore cellular structure of which the density, water absorption rate, heat conductivity factor and steam penetrating coefficient are all lower than that of other types of panel heat insulation materials, therefore it has many advantages such as: high strength light weight airtight, anticorrosion, ageing resistance and low price, etc.. It is widely used for frostbite prevention and heat prevention and heat insulation in construction industry such as highways, railways, airports, squares and family decoration, etc. which is regarded as the best thermal insulation material in the market by now.

Main Features

The machine adopts PLC computer control, so the operation is convenient, easy and simple. Vesicant is injected into the machine from 150 screw which lowered the request on polystyrene recycling material by the equipment and greatly reduced the cost of raw materials. Users can regulate freely according to requirements with automatic width and thickness regulation function,; Since CO2 foaming and automation technology in future in respect of technical control has been considered, it is convenient to change the type and to renovate, The machine uses international famous brand products for major components, so the equipment can perform smoothly with low power consumption, long service life and high efficiency. The screen can be changed conveniently during production. There are two cutting ways: blade cutting and say blade cutting for free option.

Machine Appearance

Technical Parameter

| Item | Unit | JL-XPS135/150 | |

| Extruder | 135/32 | 150/34 | |

| Heating Power | kw | 50 | 52 |

| Driving Power | kw | 75 | 45 |

| Product width x thickness | mm | 600 X (20-150) | |

| Production Capacity (approx) | m³/d | 250 | |

| Installed Capacity (approx) | kw | 300 | |

| External Dimension (approx) | m | 50 X 10 X4 | |

| Machine Weight (approx) | T | 20 | |

Layout of XPS Board Extrusion line

Main Configuration of the XPS board production line

♦ Mixer

♦ Screw Extruder

♦ Die

♦ Calibrator

♦ Haul off Unit

♦ Edge Cutter

♦ Cross Cutter

Produce Process of XPS Foam Board Production Line

Final Product (XPS Board)

Machine for Cement Fiberglass Mesh XPS Tile Backer Board

ISO9001 And CE Certification

Glimpse of Plant

Any Questions Please feel free Contact with us! Look forward To Your Email.

| Packaging Detail:In wooden case, plastic paper or wrapped with film, etc. |

| Delivery Detail:Within 45-60 days after receiving advance payment or L/C |