Light Weight Firerated Waterrated exterior wall panel for styrofoam for polystyrene houses - 1500-3000mm * 610mm

| Type: Other Fireproofing Materials | Place of Origin: Hubei China (Mainland) | Brand Name: DQ | Model Number: 1500-3000mm * 610mm |

| Color: Gray | Face panel: Non-asbestos fiber cement board | Core: EPS and cement |

LightWeight Firerated Waterrated exterior wall panel for styrofoam for polystyrene houses

It is a kind of light weight energy saving wall material taking calcium silicon board (fiber cement board) as face panel, cement, EPS, fly ash as core and forming by one time compound. It can widely be applied to wall materials of various high and low buildings such as: bank, office building, hospital, school, hotel, shopping mall, amusement hall, old house reconstruction, residence and workshop.

Specification:

Specifications | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

Thickness(mm) | 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | 180mm |

Density(kg/m2) | 45 | 56 | 64 | 70 | 83 | 101 | 119 |

Length(mm) | Standard length 2270mm for the 20'' container. Customized length is 1500-3000mm | ||||||

Width(mm) | 610mm | ||||||

Fire-proof Limits(H) | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

Remark: All kind of wall panel can be customized by customer specific requirements, such as density(kg/m2) and length of panels.

Features:

1. Energy Saving, Excellent Performance

◊ Heat Preservation: Major material for wall panel is anti-freezing, heat preserving and environmental friendly.

◊ Heat Insulation: Adjust the indoor temperature at a constant range.

◊ Fire Proof: Both face sides with 4.5mm calcium-silicon fire proof board, thus DQ Eps and Cement sandwich panel can be against a high temperature of 1000°C for 4 hours.

◊ Water Proof: Tests has proved that water containers can be made by DQ Eps and Cement sandwich panel without absorbing functions and no leakage at all.

◊ Sound Insulation: The inside of DQ wall panel material (EPS polystyrene grain) has fine sound insulation and sound-absorbing functions.

2. Easy Construction Process

◊ Easy to Install: Using our installation material (PU Foam and Cement Adhesive) is easy to build house.

◊ Shorter Time: For a 50sq. house, using DQ Eps and Cement sandwich wall panel, three people can finish it withinONEday, while using traditional block, it will take at leastSEVENdays withONE WEEKto finish.

3. High Security performance

◊ High Intension:DQ Eps and Cement sandwich wall panel can be nailed directly or have expansion bolt to lift and hang heavies, it can be covered by ceramic tile, wall paper, wood panel, coating etc.

◊ Earthquake Resistance:The Seismic performance of DQ Eps and Cement sandwich wall panel is at a magnitude of 8.5.

4. Space and Cost Saving

◊ Space Saving:DQ Eps and Cement sandwich wall panel with the thickness of 60mm-180mm, as a thin and solid new type construction material, it will save a lot of construction space compared with the traditional block.

◊ Labor Cost Saving: As DQ wall panel is easy and fast to construct.

◊ Foundation Cost Saving:As the weight of DQ wall panel is only 1/12 of traditional block, it will save 2/3 cost on construction

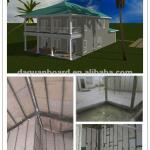

Application and Markets:

DQ Eps and Cement sandwich wall panel as a prefabricated non-load bearing wall panel, can be widely used as internal wall, external wall, floor, roof on steel or concrete structure of project such as hospital, hotel, school, office building, apartment and so on, for new construction, addition or renovations.

It has been exported to South Asia, Middle East, North Africa etc, more than 40 years around the world, which include Australian, Cyprus, Iranian, India, Kazakstan, Kirghiz, Libya, Malaysia, Nigeria, Qatar, Russia, Saudi Arabia, South African, Turkish, Thailand, UAE, Ukraine, etc.

DQ Smaples and Photos:

| Packaging Detail:1.Free packing (with normal pallet and packing belt) 2.Standard exporting packing (wrapped with plastic thin film,edge protect and good pallet): USD20-30/Package Packing size: 1500-3000*610*1000mm Loading: 18 pallets per 20' container, 11000kgs-18000kgs per 20' container |

| Delivery Detail:within one week |