Insulation glass wool board with aluminium foil - GWF-001

| Type: Other Heat Insulation Materials | Place of Origin: Hebei China (Mainland) | Brand Name: Zhenhua | Model Number: GWF-001 |

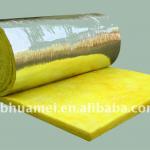

Introduction to Centrifugal glass wool products Glass wool is a kind of glass fiber and a kind of arificial inorganic wool.Adopting such natural ore as quartz sand,limestone,ect.As the main ingresdients and then coordinating with some chemical material such as soda ash and borax,ect,the glass us hence melted.Under the melting condition,floccular fibril is made via external force and blow.The fly-over crossing is taken on between fibers and then they are intertwined.Thus many fine gaps are showed out.These gaps can be regarded as pore spaces.Therefore,the glass wool can be taken on as porous material with excellent thermal insulation and sound absorption performance.

Process flow of centrifugal glass wool The main production technology of centrifugal silk throwing method of the manufacturing glass wool is:melt mixing material made if all kinds raw materials according to a certain production in the melting vault into glass liquid.The glass liquid forms a steady liquid stream through the foil leaking plate of the front furnace and then flows through the filature machine to arrive at high speed revolutionary centrifugal force,the glass liquid is thown into primary glass fiber.At the same time when the glass fiber is falling to the wool collection reticules,spray the adhesive and then compaction,solidfication,cross cutting and score cutting to form products of a certain gauge.Concentrate and packaging at last and then put into storage after boxing package. |

| Packaging Detail:The product quantity of each package is up to customers. Normal packing thickness is about 300-400mm. To meet the need of logistics distribution, Zhenhua rock wool adopts two packing forms: thermal contraction and full-closed packing. We accept OEM for different brands of products based on requirements of customers all over the world. |

| Delivery Detail:7 days |