Exported to russia,uganda,haiti prefabricated steel structure building - WZHSS-2

| Place of Origin: Hebei China (Mainland) | Brand Name: WZH | Model Number: WZHSS-2 | Product Name: prefabricated steel structure building |

| Material: H steel,C purlin,color steel, Bolt,door and window | Design demand: wind load,snow load,live load, dimension,pitch | Colum: H steel | Beam: C purlin,Square tube |

| wall panel: 0.32mm corrugated steel sheet | roofing panel: 75mm eps sandwich panel | window: pvc-steel window or alualloy window | door: Iron sliding door or electric door |

| Standard: ASTM,GB,DIN,JIS |

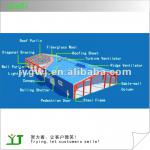

1.Breif introduction of the prefab steel structure/workshop/warehouse:

Light steel structure includes the process:design,producing and construction.It mainly has

threesystems:Main steel structure,secondary steel structure and maintainence steel

structure..

2.The following is the details of the prefab steel structure/workshop/warehouse:

| Main steel structure | ||

| No | Item | Specifications |

| 1 | Column | A:Material:welded H steel B:Technique:painted Q235 or Q345 |

| 2 | Roofing beam | A:Material:welded H steel B:Technique:painted Q235 or Q345 |

| 3 | Crane(optional) | A:Weight:5 to 15 tons B:Optional |

| 4 | Foundation bolt | A:Model: M24 to M45 B:Thickness:0.5mm to 1.3mm |

| 5 | High strength bolt | 10.9S to fixed the H steel together |

| Secondary steel structure | ||

| 1 | Roofing Purlin | A:C purlin C80-C260 B:Painted Q235B or Q345B |

| 2 | Wall purlin | A:C purlin C80-C260 B:Painted Q235B or Q345B |

| 3 | Roofing beam support | A: Steel bending B: Painted Q235B or Q345B |

| 4 | Column support | A: Steel accessory B:Paintd Q235 or Q345 |

| 5 | Bracing | A:8mm to 15m round steel B: Galvanized |

| 6 | Stay tube | A:38MM*1.5mm to 3mm Round tube B:Galvanized |

| Maintainence steel structure | ||

| 1 | Wall panel | A:950mm *50mm to 150mm eps/rockwool sanwich panel B:0.3mm to 0.6mm corrugated steel sheet |

| 2 | Roofing panel | A:960mm*50mm to 150mm eps/rockwool sandwich panel B:0.4mm to 0.6mm corrugated steel sheet |

| 3 | Window | A:alualloy or pvc steel window |

| 4 | Door | A:Steel door or sandwich panel door B:Manual or engineering |

| 5 | Ridge | A:0.3mm to 0.6mm steel roofing ridge |

| 6 | Accessory | self-tapping screws,rivets,seals,gutter,skylight sheet. |

3. For prefabricated steel structure/workshop/warehouse,needfollowinginformation

to design:

| No | Item | Specification |

| 1 | Dimension | 1.Total width: 2.Total length: 3. Building area 4.side wall height 5.Span 6.Column spacing 7.roofing pitch 8. Surface treatment 9. usage of the builidng |

| 2 | Design Index | 1.Design live load(KN/M2) on floor 2.design live load(KN/M2) on wall 3. Max crane load(Ton) 4. Max crane lift height (M) 5.Max window Load (KN/M2) 6. Max Rain Load (KN/M2) 7.Max snow load (KN/M2) 8. Max earthque Load (KN/M2) |

| 3 | Enclosing system | 1.Exterior wallmaterial and thickness 2.roofing material and thickness 3.partition wall -material and thickness |

| 4 | Window | 1.style: swing,sliding, or rolling 2. manual or engine 3. Size 4. quantity 5. position |

| 5 | Door | 1.style: swing, sliding or rolling 2. manual or enging 3. size 4. quantity 5. position |

| 6 | Others | 1.drainage system 2.ventilation 3.skylight |

4.The installation process of the prefab steel structure/workshop/warehouse:

The following is the installation process: prepare foundation→install steel column→install

columnbracing→assemble roofing beam→install roof beam→install roof beam brace→

painting again→fixed roof purlin and wall purlin→install roof panel →install wall panel→

install door andwindow→checked everything

5.The loading pictures of the prefab steel structure/workshop/warehouse:

Our company has four factories which can produce the steel structure,wall panel, roofing

panel,C purlin and other accessories ..The exported port is Tianjin port and Qingdao Port..

6. The application of the prefab steel structure/workshop/warehouse:

It is ususally used as the main steel frame of workshop,warehouse, school, shopping mall,

supermarket, Gas station,barton,Stadium, office building...

7.The advantage of the prefab steel structure/workshop/warehouse:

1.It can effectively increase the floor area utilization ratio about 6% through decreasing the

cross- section area of column and using the light weight wall...

2. Saving the energy about 50%, the wall using standard C purlin, squre steel,sandwich

panel. so it has good heat insulation and anti earquake..

3. The dead load is very light, so it has lower foundation cost

4. Fast construction, it just use about 3/1 time compared with the concrete building

5. Freindly-Enviroment,recycalbe using..

8.Other information of the prefab steel structure/workshop/warehouse:

1. Supply capacity: 10000 m2 per month

2. Moq: 50 Tons

3. Payment Term: TT or L/C sight

4. Delivery Time: wihin 30 days after receiving the deposit or L/C

5. H.S code: 9406000090

9. Our office and factory workshop:

10. Our customers from different countries:

We have exported our eps/pu/rockwool sandwich panel to austrilia,russia,new zealand,

Chile,Germany for good quality and best price..

11. Other proudcts Our company can provide:

We are a group company which has five factories.. we can produce the following building

product for u: the ppgi/ppgl steel coil,gi/gl steel sheet, corrugated gi/ppgi/ppgl steel roofing,

EPS/Rockwool/Pu sandwich panel. prefabricated houses, prefabricated steel structure...

14. The contact information of our company and me:

| Packaging Detail:standard and seaworthy packing (waterproof paper + polyethylene rush inhibitor ,the antirust paper , the ring of defendse on inside and outside, steel belt , and the guard plate .) |

| Delivery Detail:within 30 days after signing the contract or L/C sight |