Building exterior decorative partition walls fiber cement

| Place of Origin: Shandong China (Mainland) | Brand Name: Sinsobond | Feature: Perforated,against moth,can be nailed,can be sawn,can be drilled... | Type: Fiber Cement Boards |

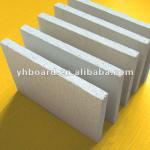

| Surface: Rough side,smooth side,sanding side | Thickness: 4mm,4.5mm,5mm,6mm,8mm,10mm,12mm | Fireproof level: A1 Level fireproof performance | Standard size: 1220x2440mm or 1200x2400mm |

| Packaging: Pallet packaging | Usage: ceiling, interior/exterior partition and outer wall decoration | MOQ: 2x20GP for each thickness | Customized: Available |

| Material: High quality Partland cement,silver sand |

| Size | 1220x2400mm |

| Thickness | 4mm,4.5mm,5mm,6mm,8mm,10mm,12mm |

| Surface | Rough side,smooth side,sanding side |

| Usage | interior/exterior Partition,Ceiling,outwall decoration... |

| Besides | Other special size canbe made by the customer's requirement |

| Spec | Test data | Inspection basis |

| Density | 1.34g/cm3 | GB/T7019~1997 |

| Dry state bending strength | 11MPa | GB/T7019~1997 |

| Water saturation state bending strength | 10MPa | GB/T7019~1997 |

| Bulking factor | 0.2% | JC688~2006 |

| Formaldehyde release | <0.1mg/L(qualified) | GB18580~2001 |

| Activity coefficient | qualified | GB6566~2001 |

| Combustibility | A1 Level | GB/T5464~1999 |

| Moisture absorption | 0.12% | GA 160~2004 |

| Impermeability | no water drop at the buttom | GA 160~2004 |

| Contract with dry rate | 0.1 | JC688~2006 |

| Thermal Conductivity | 0.117kca/mhC | JC/T5641~2008 |

Process:

1. High density fiber cement board as substrate.

2. UV painting on the surface, Glossy and Matt for Every Pattern.

1. MOQ: 2x20GP for each thickness

4. Payment Terms: 30% prepayment, balance within 10 days of the signed B/L

5. Packaging: Pallet packaging

Fiber cement board Packaging

Method Construct:

The waytoctu and construct the fiber cement board is the same as the calcium silicate board!Use self tapping screw to fixed on the keel,after put joint mixture on the gap in between ,if you use the fiber cement board in washing room or other places where are wet or contains water,it should be reinforce the waterproof to ensure the entire waterproofing system!

Fiber cement board Application

Used for ceiling, interior/exterior partition and outer wall decoration etc.Such as Business building, Entertainment facility, supermarket, hotel & restaurant, factory, warehouse, apartment building, hospital, theater and station etc.

Pallet Packaging

Shall you have any question or inquiry,please kindly feel free to contact us ,Thanks!

Best Regards!

| Packaging Detail:Pallet packaging |

| Delivery Detail:15 days after receiving prepayment or L/C |