architecture membrane - NL-LT-3218

| Type: Architecture Membrane | Place of Origin: China (Mainland) | Brand Name: Vita Media | Model Number: NL-LT-3218 |

| treatment: weldable PVDF/Acrylic | Guranteed: 10 years/ 20 years | tensile strength: 4200/4000 | tear strength: 500/500 |

| peeling strength: 90 | fabric: 100% PES | coating: knife coating process | color: standard white |

| size: 2.04mts*50mts | application: architecture membrane |

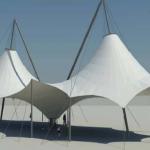

| Large-scale tensile structures have only become popular in the latter part of the 20th century, but have long been used in tents, where guy ropes are used to provide pre-tension to the fabric membrane, which ultimately, allows it to withstand structural loads. In fact, since the 1960s, tensile structures have been championed by designers and engineers the world over including Ove Arup, Buro Happold, Walter Bird and Frei Otto. Often considered the fifth dimension' in building materials, experts in the industry insist architectural membrane rivals concrete, glass, timber and steel in terms of its effectiveness and value as a building and design material. Barry Patten's design for Melbourne's Sidney Myer Music Bowl in 1956 represents perhaps the earliest use of architectural membrane on a tensile structure. |

| Description: Calendar Tarpaulin NL-LT-3218 base fabric: Polyester yarn: 1000 x1000/ 2000D*2000D/1500D*1500D construction: 9*9,12*12 weight: 900/1050/1200gsm/sq.m adhesion: 90 N/5cm features: •waterproof •opaque blockout up to 99%, also available in translucent •acrylic lacquered, PVDF lacquered •anti-ultraviolet radiation, anti-aged •weldable and show a strength up to 9%% at 23oc (70% at 70oc) application: •stadiums, •sports facilities, •exhibition halls, •business centers, •concert halls and etc.; •shade roofs of the entrance of hotels, •restaurants, cafes, •and other commercial buildings; •airport roofs, bus, train stations and terminals, •car parking and gas stations; •other permanent or temporary structures |

| PVC+Polyester A very popular fabric, PVC has been used in structural membrane structures for more than 30 years. It has durability properties that are usually guaranteed for more than 20 years and needs very little maintenance over that period. Owing to its proven versatility and flexibility, PVC is generally considered the most popular membrane. PVC is usually used on umbrella structures and custom membrane structures where aesthetics and lightweight properties are particularly important. ETFE Ethyltetrafluoroethylene (ETFE) is lightweight (it weighs 1% of the equivalent-sized glass panel), highly transparent to UV light, weather resistant, has better insulation properties than glass, is completely recyclable and can support up to 400 times its own weight. Available as either a single layer tension membrane or as a two-or three-layer cushion, ETFE can decrease energy consumption by 30% compared to glass. ETFE can be inflated, to provide superior insulation properties or for aesthetic effect-as on the Allianz Arena in Munich and the Watercube in Beijing. ETFE cushions can also be etched with patterns in order to let different levels of light through when inflated to different levels. They are most often supported by a structural frame and maintain transparency and strength for approximately 20 years. ETFE is also highly resistant to fire and heat. PTFE+Glass Fiber Polytetrafluoroethylene (PTFE) is a versatile, hydrophobic membrane available laminated to various support materials or unsupported. PTFE membrane has broad chemical compatibility, excellent particle retention, and easy handling and sealing. The PTFE coating is chemically inert, capable of withstanding temperatures from -73C to +232C (-100F to +450F). The low surface free energy of the material creates a surface which is readily cleaned by rainwater. It is also completely immune to UV radiation. This unique combination of inertness, thermal stability and surface properties make PTFE fluoropolymer coatings ideal for products requiring superior weather and fire resistance. |

| Packaging Detail:Kraft Paper + Air Bubble + Patten Cork + Exclusive ID Code |

| Delivery Detail:30 workdays after advance payment |