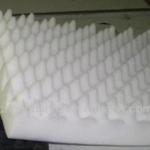

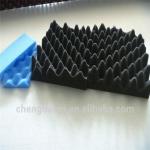

Acoustic Melamine Foam Panel - ew01

| Type: Acoustic Panels | Place of Origin: Henan China (Mainland) | Brand Name: Enworld | Model Number: ew01 |

| Acoustic Panel Type: Acoustic Foam Panels | color: white, grey | shape: square | size: customized |

| density: 8.5kg/m3 |

Acoustic Melamine Foam Panel

Melamine foam has three-dimensional grid structure and high opening rate (the opening rate of melamine foam with density of 8-16kg/m3 is 99%). Sound wave, therefore, can go into the innermost of foam conveniently and effectively and transformed to vibration of grid, thereby being consumed and absorbed and eliminating reflected wave effectively as well. It has good sound absorption property in a wide audio range, especially low-frequency noise. Tests show that sound absorption factor is within 0.85~1.07 in terms of 315Hz~500Hz low-frequency noise when melamine foam has a thickness of 8cm.

Main 8 characteristics of the product

1. High flame resistance. Tested to CN standard GB 8624-2006/B-s2, d0, t2 level (equal to German DIN 4102 B1 level and Americas UL 94-96V-0 level) in flame proofing without any flame proofing agents. When subjected to open flame, it will form a layer of coke on the surface obstructing continued burning producing no liquid or poisonous gas or smoke. Melamine foam will self extinguish.

2. High sound absorption. With 95% open-cell, sound waves can easily enter the inner part of the Melamine foam and absorbed in the vibration of the fiber net. re-radiation is also prevented.

3. Good heat insulation. The 3D fiber grid net construction of Melamine foam effectively blocks heat transmitting air movement, due to its 95% open-cell properties.

4. High resistance of high temperature. Suitable for long-term working in 200-240 Celsius. No breaking down or deformation under 400 Celsius.

5. Low density. The density of the product is 4-12kg per cubic meter; the lightest foam plastic available.

6.Safe, hygienic, and non-poisonous. Stable formation and chemical construction has special chemical stabilization properties. Melamine foam can be applied to all interior applications including commercial, industrial, transportation and domestic.

7. Convenient deep processing and installation. Melamine foam can be processed into cylinder, sheet,or other shaped materials by cutting, filing, or other ways. In order to increase the area for better sound proofing effect, the surface can be processed as cone or wedge-shape. In addition, it also can change various shapes as requirement by hot press process. Original adhesive without other installing measures can fix the material on metal and nonmetal surface. Generally, melamine foam panel with double faced adhesive tape is popular among customers.

8. Extremely durable. Melamine foam can keep from weathering, decomposition, shrinking under the conditions of great heat, high pressure, high humidity, and high wind speeds.

Applications :

1. Sound proofing panel for apartments, schoolrooms, caferterias, restaurants, office buildings, and machine rooms.

2. Baffles in sound recording studios.

3. Suspended ceiling baffles in buildings with high ceilings: theatre, cinema, church.

4. Sound proofing panel as the inside layer in railroad car or subway car.

5. Heat and noise management in cars.

6. Heating, ventilation and air conditioning linings, pipe lagging.

| Packaging Detail:Packed by thick opp bags. |

| Delivery Detail:Within one week after the deposit. |