Standard Ultrasonic Welding Machinery for Geocell - TGGS

| Type: Geocells | Place of Origin: Shandong China (Mainland) | Brand Name: Z.K. | Model Number: TGGS |

| Material: HDPE,PP | Standard: ASTM | Color: black, yellow, green, white or customized | surface: smooth or textured |

| hole: with or without | tensile strngth on welding point: more than 1000N/10CM | thickness: 1.0mm to 1.6mm | welding distance: 330-1000mm |

| height: 50-300mm | certificate: ISO, CE | Manufactory: Yes |

HDPE geocell

1.Material:HDPE or PP

2.Weight:50-250mm

3.combining power of welding spot:560-2560 N

4.Weding distance:400m

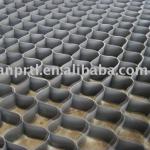

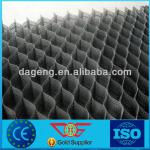

Geocell is consisted by high intensity HDPE wide ribs,,shaped in reticulation after hard welding .It has retractile performance,can be folded when transport,and fill stone material or concrete when extend it,formed a whole soild structure.It increase the bearing strength of groundwork,also canbe used in slope as protecting framwork.

Geocell for soft soil foundation and protection is a relatively shallow cellular confinement system which is used to combat erosion on slopes up to 1:1. The geocell is fabricated using a geotextile so it is permeable and allows water to flow between cells encouraging drainage and vegetation.

anti-aging

resisting acid and alkaline

homogenous structure

the best sidewise restriction

soil-fixation

concenient and fast construction

Light weight, wear-resistant, chemical stability, light oxidation aging, anti-acid/alkali corrosion, applied to different geological conditions, such as saline soil, desert, etc.

- Wide temperature range, high tensile strength, good rigidity and toughness, good load capacity and anti-erosion ability.

- Size is relatively stable, change the height and welding distance can meet the needs of different projects.

- Retractile, easy to transport.

- Easy to use, can use the local materials and achieve rapid construction, reduce construction costs.

- Can be used repeatedly.

A. firm for the railway roadbed

In order to prevent gravel gradation lateral movement is stronger as a whole to prevent the pumping, even if the soft ground can prevent the collapse of the whole or in part, the large volume of traffic in areas such as the Cross Road, bifurcation Road and turn, can significantly increase the use of Number of years.

B. for a solid roadbed

Can generate high power and flexibility of both traditional and rock embankment on the basis compared to the basis of thickness can be reduced more than 50% of the gravity and contact with the pressure and reduce the horizontal dispersion and can be used when the account or on a permanent road construction .

C. used to bear the gravity of the dam wall

Strengthen the definition of gravel to form the structure of the body has to stop cross-cutting pressure, no matter slide and pool formation, can itself be supported by non-structural surface layer and the natural plant, or a vertical ladder-type design.

D. shallow water for river training:

Three-direction grid to enhance the strength of avoid fill soil erosion and increase the load, can reduce the cost of construction of the shallow river and allow river traffic with the design and a variety of soil conditions.

E. support for the pipeline and sewer:

To use a more solid foundation for the pipeline, the construction is simple, reducing the excavation, do not have to lay many rocks and avoid part landslide in the long run.

F. used to prevent landslides and heavy-duty force by the retaining wall mixed:

Do not have to use the template structure can create a solid wall, and backfill side firmly into the price of one, even if the traditional structure of a variety of gravity is not available, fill materials can also significantly reduce the cost of the project.

G. independence for the strong terminals, such as dams room.

Can be quickly wall structure independent from the independent wall, and the use of water in the granular to protect dam, or weir wall, if temporary facilities are to be removed also Geocell back at the pier or breakwater and other important coastal Also use a wide range.

1,To stable the roadbed of railway.

2,To stable the roadbed of highroad.

3,To bear the load of dike or retaining wall.

4,To the improvement of shallow riverway.

5,To support the pipeline and sewer.

6,For the prevention of landslide by useing geocell as a heavy-duty hybrid force retaining wall.

7,To be used as independent wall, wharf and breakwater, etc.

8,For the desert, beaches and the riverbed, the river bank's regulation.

Geocell for soft soil foundation and protection Index

Item Model | Height (mm) | Welding distance (mm) | Sheet thickness (mm) | Tensile yield strength of the cell (MPa) | Seam peel strength (N) | |

| smooth | textured | |||||

| TGLG-50-400 | 50 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 500 |

| TGLG-100-400 | 100 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

| TGLG-150-400 | 150 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1500 |

| TGLG-200-400 | 200 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 2000 |

| TGLG-75-330 | 75 | 330 | 1~1.1 | 1.4~1.5 | 20.0 | 750 |

| TGLG-100-330 | 100 | 330 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

| TGLG-150-330 | 150 | 330 | 1~1.1 | 1.4~1.5 | 20.0 | 1500 |

Notes:(1)welding distancecan be made: 330mm, 400mm, 500mm,550mm or according to the demands (2)The special spec or size can be manufactured according to the demands of the contract | ||||||

| Specification | height (mm) | Reverting joint distance (mm) | Open length (mm) | Open width (mm) | Plate tensile strength ≥MPa | Elongation (≤%) | Reverting strength (≥KN/m) |

| TGLG50-500 | 50 | 500 | 12500 | 4000 | 150 | 15 | 15 |

| TGLG100-500 | 100 | 500 | 12500 | 4000 | 150 | 15 | 15 |

| TGLG150-500 | 150 | 500 | 12500 | 4000 | 150 | 15 | 15 |

| TGLG200-500 | 200 | 500 | 12500 | 4000 | 150 | 15 | 15 |

| TGLG80-500 | 80 | 500 | 12500 | 4000 | 150 | 15 | 15 |

Remarks: Width of the product can be made according to the customer's demand, and other special standards will carry out by agreement or contract |

| Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

| Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

| Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

| Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ASTM D 5199 |

| Cell Details | welding distance:330-1000mm |

| Cell Depth | 50-250mm |

| Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

| Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

| Certification | CE ,ISO |

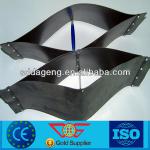

Steel enhance Geocell in Georgia Room of the ordinary plastic sheet to add low elongation of the wire by a composite sheet, formed through the riveting three-dimensional honeycomb grid, the biggest characteristics is: anti - High tensile strength, low elongation.

Methods used

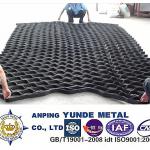

In construction, the geocell can be pulled into a network and launched into a three-dimensional honeycomb grid, then filled with soil, macadam, concrete or other granular materials to constitute to be a structure with strong lateral restriction and large stiffness.

Concrete construction method

- Open the superimposed geocell.

- Fixed with nails or connected with the framework of stretching device.

- Fill the particle filler until the full and beyond standard room to the top, then vibrate or roll to finish the primary work.

- At this point, cell chamber system can support all kinds of construction equipment. The construction can be done directly in the above.

| Packaging Detail:OurHigh quality CE certified HDPE Geocell for roadbed, slope is Standard export Packing Or Packed as customers' requests |

| Delivery Detail:15 DAYS after the receipt of the payment |