low price and high quality asphalt reinforcement fiberglass geogrid - YG-2771

| Type: Geogrids | Place of Origin: Hebei China (Mainland) | Brand Name: YG | Model Number: YG-2771 |

| Material: Fiberglass |

low price and high quality asphalt reinforcement fiberglass geogrid

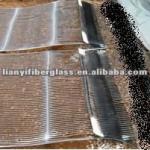

Fiberglass Pavement Mesh is a product that uses a continuous coating of fiberglass as an ideal highway pavement reinforcement.

It is characterized by high tensile strength in both axial and lateral direction, low stretch rate, high temperature-resistance, alkali-resistance, easy construction, and low price. It can be used on pitch pavement, bituminous concrete pavement, and cement pavement to prevent cracks and prolong pavement service life. It also can be used as basal reinforcement material on hillsides, reservoirs, harbours, ports, water channels and sea walls.

Characteristics:

- High tensile strength

- Low elongation coefficient

- .No long-term creeping effect

- Fine compatibility with pavement materials

- Good stablity at high temperature

- Alkali-resistant

- Interlocking functions

- Consistency

Used on new and old major roads, the material is paved between the base course and the top course, or between the top courses. It can effectively improve surface stress distribution, resist and retard the surface cracks arising from the base course cracks, and therefore the highway road service life is prolonged - and its construction cost is lowered compared to that of traditional roads and pavements.

Specifications:

- width 2 to 4 meters maximum

- roll length is 50 or 100 meters

- standard mesh size is 25mm or 12mm

- self-adhensive is also available

- polyester also availiable

Technical Data of Fiberglass Geogrid | |||||||

Sort | Type | Rupture Intension (KN/m) | Rupture Tensibility(%) | Gridding Size(mm×mm) | Breadth(m) | ||

| Warp | Weft | Warp | Weft | ||||

Fiberglass Geogrid | EGA25-25 | ≥25 | ≥25 | ≤4 | ≤4 | 12~50 | 2~6 |

| EGA 30-30 | ≥30 | ≥30 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA40-40 | ≥40 | ≥40 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA50-50 | ≥50 | ≥50 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA80-80 | ≥80 | ≥80 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA100-100 | ≥100 | ≥100 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA120-120 | ≥120 | ≥120 | ≤4 | ≤4 | 12~50 | 2~6 | |

Self-adhesive | EGA25-25 | ≥25 | ≥25 | ≤4 | ≤4 | 12~50 | 2~6 |

| EGA30-30 | ≥30 | ≥30 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA40-40 | ≥40 | ≥40 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA50-50 | ≥50 | ≥50 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA80-80 | ≥80 | ≥80 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA100-100 | ≥100 | ≥100 | ≤4 | ≤4 | 12~50 | 2~6 | |

| EGA120-120 | ≥120 | ≥120 | ≤4 | ≤4 | 12~50 | 2~6 | |

Properties:

1) High tensile strength:the strength-to-weight ratio of fiberglass is greater

than that of plain carbon steel. At 20oC, the ratio of its elastic modulus to that of asphalt concrete is 20:1. Thus it is strong enough to prevent deflection cracks.

2) Low elongation:the fiberglass grid stress diagram shows as a vertical straight line, which indicates that its ability of deforming resistance is very high and its break elongation is less than 4%.

3) Creep resistance:fiberglass grid is not subject to creep, unlike many other materials. When bearing a load for long periods, fiberglass grid will not permanently deform.

4) Chemical compatibility with surfacing materials:Fiberglass grid is coated with an inorganic sizing that makes it chemically compatible to all the materials used in surfacing mixes.

5) Wide temperature range:the melting point of fiberglass is 1000C, while that of hot asphalt is 160C. Therefore, fiberglass grid is unaffected by the highest temperatures experienced in road surfacing. It is also unaffected by low temperatures and retains its strength in temperatures as low as 100oC. Unlike other materials such as carbon fiber, Kevlar fiber,steel rib and plaster fiber, the elastic modulus of fiberglass is not affected by temperature change.

6) Physical and chemical stability:fiberglass grid is treated with special inorganic

sizing that makes it very resistant to physical wear and a wide range of corrosive environments created by chemical, biological and climatic changes.

7) Nesting, interlock and restraint effects:asphalt road mix extrudes

| Packaging Detail:with weaving bags or as per request |

| Delivery Detail:within 10-15 days once we receive the deposit |