Chinese plastic modular formwork for concrete wall - CPANE0120

| Place of Origin: Zhejiang China (Mainland) | Brand Name: bofu | Model Number: CPANE0120 | product name: formwork |

| weight: 11kg | color: black | size: 120x60x7cm | material: PP |

| tensile strength: 40 KN | brand: BOFU | reusable: 100 times | model: CPANE0120 |

Specifications

1. light weight, high strength

2. sustainable and enviroment friendly

3. reusable

4. eco-friendly

5. easy operation

Product Description

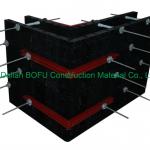

Modular formwork is an easy and intuitive system of PP formworks for building concrete walls, basements, columns. Compared with the traditional timber or steel systems, modular formwork is handier, more cost effective and faster to set up, save time and labor charge. Modular formwork has panels of various sizes, fastened together by means of fast-lock nylon handles. Thanks to the several possible panel combinations, and special inner and outer corner elements, the possible wall thickness goes from 10 to 40 cm.

Concept

Dalian BOFU Construction Material Co., Ltd. is the professional supplier of formwork, scaffolding, couplers, prop, etc. As the leading supplier of modular formwork in North East China, BOFU endeavour to help you build faster and conveniently, and most important, guarantee the safety for workers. BOFU also endeavour to protect environment because we only have one earth.

Thanks to our credibility and high quality products, BOFU has built long term cooperation relationship with many world class enterprises such as Saudi Arabia ATCO group, Russia Sakhalin Energy Investment Company, Italy Geoplast Company, etc.

Product Characteristics

| product name | Modular formwork |

| origin | China |

| color | Black |

| material | PP |

| weight | 11kg |

| tensile strength | 40KN |

| brand | BOFU |

| reusable | 100 times |

| model | CPANE0120 |

Product Introduction

Handier

The biggest panel is 120x60cm, weight only 10.5kg, whichcan be lift and set up by only one person easily, need no

crane on the site.

easy set up

Different size of panels can be firmly locked bysimply turn the special handles to 90 degree. The

panels have rib on the back, which makes thesystem need not traditional wood blocks and nails.

The panels have holes to fit tie rod, guarantee thestrength of the whole system.

Strength

The material of modular formwork is PP (polypropylene) mixied with special glass fibres which enable panels to hold high pressures. The handles are made by high strength Nilon, each panel

locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

enviroment friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment. In practice using, the corner of panels is easier broken relatively compared with the panel itself, our modular formwork have 4 small corner pieces to be replaced seperately, makes the panels can be reused about 100 times.

Consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth,can be left without rework.

Walls and corners

Using modular formwork, it is possible to pour up to 40cm thick and 3 meters highstraight walls one time. Combining with special corners and compensation panels, right angle walls, three way T-walls and four way cross walls can be fomed easily. The low weight and modularity of modular formwork makes it ideal for fence walls as it is possible to move large gangforms by hand.

Basins and elevator shafts

The low weight of modular formwork simplifies the pouring of tanks, basins and swimming pools in

areas with limited or no access to heavy equipment. Modular fomwork also ideal for elevator shafts as it can use without aid of crane, can make an easy, fast and precise job by hand.

Doors and windows

To make doors and windows by modular formwork is simple, by inserting inside the formwork a wooden frame corresponding to the size of the opening needed, and then pour the walls with doors and windows.

Adjustable Column panel

The column panels are interconnected using the standardnylon locking handles. Each panel will require 9 handles.The forming face has 6 parallel rows of fixing holes toallow the orthogonal connection of the panels in a “star”shape. The rows are placed at a distance of 100/50mm theone from the other, allowing the forming of square and/orrectangular columns with side of 150 to 600mm.

Set up Showing

project Sample

Please send your project design drawing in .dwg to us, we will help to make formwork solution for you.

formwork

| Packaging Detail:plastic pallets with plastic film, pallet size: 120x80x15cm, 100x80x15cm |

| Delivery Detail:30 days |