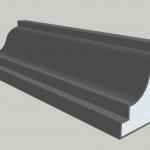

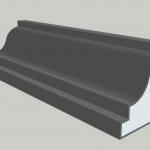

SA EPS Foam Shape Hard Crack Resistant Coat - SA800

| Place of Origin: Shanghai China (Mainland) | Brand Name: SA | Model Number: SA800 | Usage: Joint Mortar,Building Coating |

| Type: Cement Mortar | Main Raw Material: Cement , Sand , additives | State: Powder Coating | Color: Mainly grey |

SA802 EPSFoam Shape Hard Crack Resistant Coat With 110g/m2 Reinforcing Mesh Self - adhesive Embedded

·Designed Especially for Foam Shape Coating

· Excellent Adhesive for EPS Foam Shapes to: EPS Foam, wood, masonry, cement backer board,

poured in place concrete

·Goes on Smooth and Easy

·Rock Hard Coating & Adhesive

· 50 pound bags and can be purchased by the bag, pallet or truckload.

· Tintable with Dry or Liquid Pigments

· Excellent to Hard Coat Props, Theatrical Sets, EPS Foam Shape, EIFS Arhitectural Pieces

· Sets Hard Like Concrete

Field of application:

The function of this product is to protect the EPS corince and fix the fiberglass mesh

Benefits of SA Coats:

· Fast set times, fast cycle times, short cure times.

· Superior hardness and easy to apply.

· Water resistant and chemically inert once cured.

· Safe for humans and animals.

· Tough, stable surface coating for decorative building items, artificial landscapes, stage props, sculptures, etc.

· Structural foam that’s light weight, reducing the need for structural support.

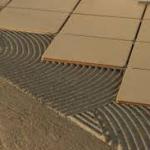

Consumption

4.5~6 kg/m2

Mix ratio with water

5.5 liter/ 25 kg powder, 0.22 l/ kg powder

Technical Data

Items | Data | Test Method | |

Pull-off strength (with EPS board) | Original | ≥0.10 Mpa (EPS damaged) | JG 149 |

| Water resistant | ≥0.10 Mpa (EPS damaged) | ||

| Freeze-thaw resistant | ≥0.10 Mpa (EPS damaged) | ||

Flexibility property | Compressive strength/flexural % (cement base) | ≤3.0 | |

| Cracking strain % (non cement base ) | ≥1.5 | ||

Processing/working time | 1.5~4.0 h | ||

Remarks:

1)Only mix with water, no other addition

2)The temperature of air and mixture mortar must be from 5°C~35°C

3)The mixture must be used up in 2h

4)Avoid sunshine, high temperature and freezing

5)Avoid strong wind during application

6)Avoid rain during application

Shelf life and storage:

6 months after manufacturing date in dry ventilated place

Application on villaes

| Packaging Detail:In 25 kg ( 55 lbs) bag |

| Delivery Detail:5 days |