Ceramic tile glue, building construction material of tile adhesive - L-300

| Type: Tile Accessories | Place of Origin: Anhui China (Mainland) | Brand Name: Lencaqi | Model Number: L-300 |

| Tile Accessory Type: tile glue |

Ceramic tile glue

Product description:

Ceramic tileadhesive is made of high quality inorganic cementitious materials, fine aggregate and polymer additives, have good cohesiveness, permeability resistance, aging resistance and good water resistance, heat resistance and freeze-thaw resistance.

Product features:

1.Strong cohesive force, saving material, safe, firm, avoid empty drums or falls off

2.Don't soak wet brick wall during construction, can significantly improve work efficiency, convenient andefficient,

3.good permeability resistance and anti-aging performance

4.has elastic, can absorb the swell-shrink between substrate and ceramic tile,effectively prevent ceramic tile generate cracks, thereby extending the service life of ceramic tile,

5.This product is non-toxic, tasteless, green environmental protection.

Range of application:

Indoor and outdoor cement, ceramic tile, marble, clay brick or walls and floors which composed of wood substrate, Long-term immersion of bathrooms, pools, etc.Particularlysuitable for directly paste tile on the surface of polymer cement waterproof coating.

Method of application:

1.one side stirring slowly the other side pour the powder into water,According to ceramic tile adhesive:water=4:1 (25 kg/bag, about 6 ~ 6.5 kg of water) to form homogeneous paste, electric mixing effect is best.If let stand for 10 minutes before once again stir can increase the strength.Also can adjust water amount according to different ceramic tile’s bibulous rate, facade stickup ceramic tile is not fallingas norm.

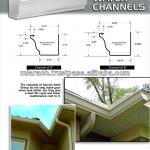

2.use tooth type scraper make mucilage was applied to the work surface, uniform distribution, adjust the Angle between scraper and working face to control the thickness of the mucilage, every time daub about 1 m2or so, and then put ceramic tile on it

3.Such as the ceramic tile whose back groove is deeper or paste stone material, in addition to wipe pulp on the face, also should wipe pulp on the back of tile and SLATE.

Base treatment:

Base surface must be firm, smooth, no dust, no pollution, no cast and other dirt.Loose strong water imbibition’s base should be water wet.

Reference dosage:

demand amount of per unit area according to project’s specific situation may different base surface is more smooth, less dosage of sizing agent.

For Your Information:

3x3mmtooth type scraperneed about 1.7kg/m2

6x6mmtooth type scraperneed about 3.0kg/m2

10x10mm tooth type scraperneed about 4.5kg/m2

Technical parameters:

Adjustment time: 20-25min

Open time: 15min

Surface dry:2h(20°C),hard dry:24h(Depending on the climate)

Packing.

25 kg/bag

Storage:

Storage life in normal transportation and storage condition is one year.

Statement:

The company ensure the quality of the product, but is not liable due to use of incorrect, designed by the company in the construction project, the company promised five years warranty.

Working process:

Pictures:

| Packaging Detail:25kg/bag |

| Delivery Detail:10 days |